Brief Overview Of Grain Threshing Process

The threshing is one of the most crucial tasks which is involved in the entire work mechanism of a combine harvester. This process involves the separation of the grains from the rest of the crop. The agricultural equipment can be used for the threshing procedure, and it is fastening it in comparison to doing it manually. The combine concave equipment plays a crucial role in performing the functions of reaping, threshing as well as winnowing. This grain threshing procedure is accomplished by carrying out the most suitable adjustments between the combine concave and the cylinder.

The Proper Combine Adjustment Is Crucial To Increase Efficiency Of Grain Threshing

The proper combine setting plays a crucial role in determining the efficiency of the threshing grain process, minimizing wastage. The poor combine adjustments will not only result in the loss of yield but also reduce the overall grain quality.

The threshing process is undeniably the corner store of the harvesting operation, and this is the reason maximum efficiency can be achieved with the help of the modern and advanced system.

The Estes Performance Concave provides advanced agriculture equipment in which the notched bar is precisely engineered to maximize threshing efficiency. It brings upon a 137% increase in effective threshing surface area in comparison to the round bar concave. So, maximizing the threshing procedure means all the grains will be threshed as well as captured sooner. Also, the majority of the cover plates are solid, just like the bands or even the fillers. The solid coverage on the concave provides three advantages:

The first is that there is less possible surface area for letting the smaller grains escape onto the augers while threshing. Also, covers present on the concave will lead to the distribution of the grains on the augers in an even manner.

As soon as the grain threshing takes place, they are captured. This means that there will be less grain damage during their exit from the concave.

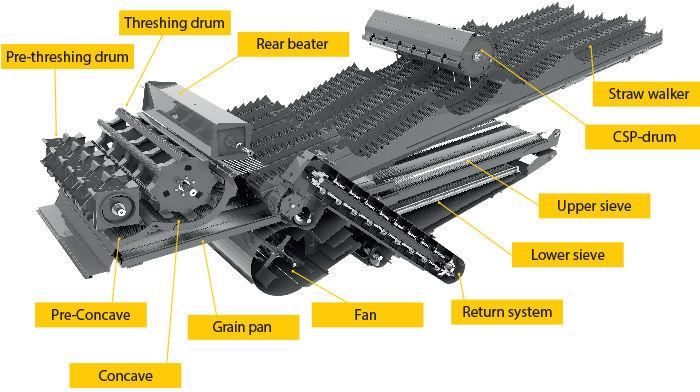

How Combine Concave Work In a Tangential Threshing System?

In the tangential threshing system, there is a clearance existing between the cylinder as well as concave, and it is quite wide from where the material is coming into the threshing unit. However, it is the smaller size at the point of escape. The calculation of the clearance distance is done readily from the outer diameter of the cylinder towards the bar’s top surface. The ratio in between the clearance value towards entrance along with the exit of the threshing space is lying between 3 to 5.5 in cereals along with 1.8-2.5 in corns.

How Combine Concave Work In Axial Threshing System?

The concave in the axial threshing system possesses several of other distinctive features. The rotary threshing system requires elevated to power. The cage of the combine is fixed. Also, the concave lying underneath the cage is being built with the help of three or four interchangeable and adjustable sections for executing the tasks with various crops in all types of specific farming conditions.

Buy Most Ideal Combine Harvester For Optimizing Grain Threshing Process

The Estes Performance Concave will provide you with the ideal combine harvester so you can turn to greater efficiencies during the grain threshing process. Knowing well how to perform harvesting operations optimally, tuning towards clearance, and at the same time carrying out the most accurate adjustments will help the farmer get maximum productivity. For more details about the combine concave systems, land on the website today!