The corn crop is grown during the hot and dry summer season. The harvesting of this crop should be conducted as soon as the grain matures. Also, at the same time dries out with the optimum moisture level. This particular crop takes a bit later time than others to mature. When the corn crop reaches a certain level of maturity, a black layer is formulated towards the kernel base, also when the accumulation of hard starch is completed. The best time to start crop harvesting varies to a great extent. It depends on the duration which will be taken to harvest the crop. To maximize the efficiency and speed of the harvesting process, modern-day agriculture producers utilize farming combine concave harvesters. Since the corn crop is more susceptible to the damaging due to the high moisture content. Thus, for the proper harvesting procedure, it is best to keep the moisture level to around 15-22% for the best results. The majority of the kernel losses during the harvesting time take place due to mechanical limitations with the settings of the combine concave. This particular equipment has three main functions to be performed during the harvesting process. This includes picking, threshing along with grain cleaning.

Adjustments to be made in farm combine settings for efficient harvesting

By making the proper adjustments in the farm combine setting, agriculture producers will be able to reduce the significant volume of losses that may occur during the entire harvesting process:

Ground speed This is one of the crucial factors to control for improving corn harvesting efficiency. By matching combine ground speed with the crop throughput as well as the harvesting conditions, there will be an improvement in the efficiency. If the ground speed is too high, it will result in greater losses. However, if the rate is being too slow, this reduces the threshing efficiency and results in increased consumption of fuel.

- Header loss

The header loss takes place when kernels will not be capable of making into the machinery. The contributory factor to the head or loss may be biological or mechanical. For example, when the crop is too dry, it is going to shatter, leading to the loss of the ears. When the deck plates are being set wide, it leads to excessive ear shelling. Making the proper adjustments to the header speed and the relative ground speed will lead to the header loss more slowly.

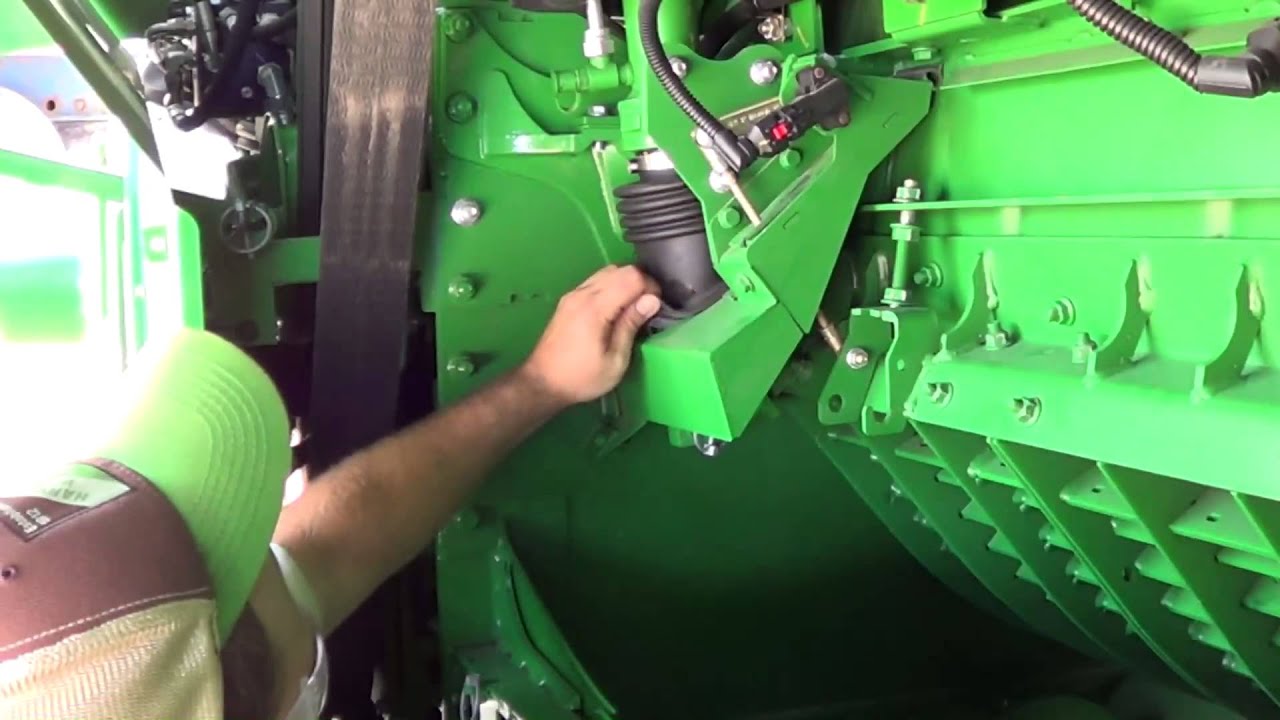

- Cylinder or rotor adjustment

Just like other crops, the adjustments in the rotor or cylinder will have a significant impact on the quality of corn. As much as 80% of the corn kernel damage occurs during the shelling process. So careful management will produce dividends throughout the process of storage and drying. The moisture content has a significant impact on grain damage.

- Sieve as well as chaffer settings

The grain losses can also occur when it passes through the sieve and the chaffer. The grain losses will be reduced through the adjustment in the fan speed. Due to the large volume of the trash, the canals will stay within it. This is when straw walkers exist in the conventional farming combine or over the cleaning shoe within the rotary design.

Achieve greater profitability by purchasing farming combine from Estes Performance Concaves

The speed and efficiency of the harvesting is the focus of the leading farm combine concaves manufacturing company Estes Performance Concaves. The most advanced & latest models can cover 200 acres of area in diverse weather conditions. So purchasing the farming combine from the Estes Performance Concave company is undeniably the best tactic to achieve greater output, profitability, and return on investment!