Harvesting high-moisture corn approximately 25 percent and up, creates its own distinct set of challenges as compared to harvesting the dry corn.

Wet corn can affect combine capacity, losses, and grain quality unless adjustments and configuration changes are made because of the differences when harvesting high-moisture corn.

The information that we have mentioned here will help the operators to adjust or configure their John Deere Combine Settings when harvesting high-moisture (wet) corn by listing the steps, starting at the front of the combine and working through the combine, similar to crop flow.

Significance of John Deere S Series

It is not a single machine but a collection of a series of machines working as one unit. This is basically deals with various aspects of harvesting in a seamless fashion. As a result it is essential is made operative by giving the authentic settings.

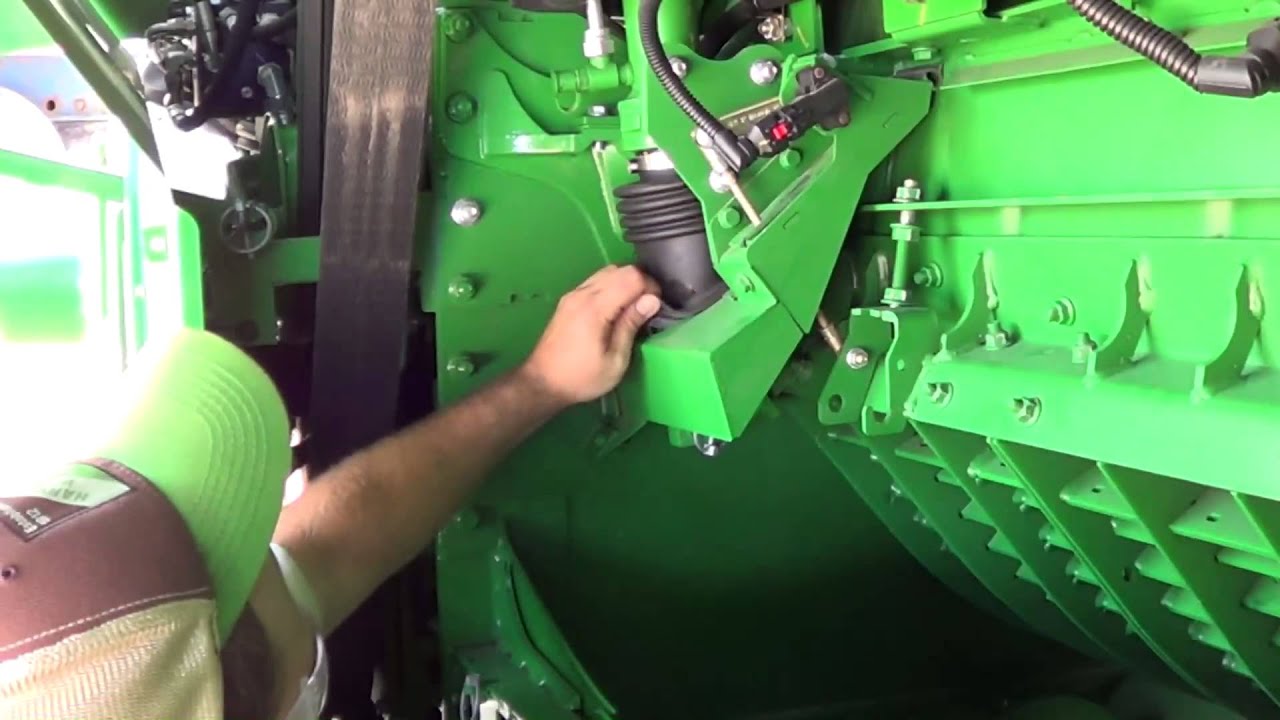

Examining The Various Parts on Your Combine.

Below is the list of checking that the John Deere Combine Settings performs.

Finding Ground Speed

It is quite obvious that each and every operator are not comfortable while running at the same speed. This is totally dependent on the operator. Now, this has a profound impact on how the “combine” mechanism..

Setting the Machine

Please take into consideration that the machine you are launching is nothing but various machines working under one roof. That is the sole reason due to which it is referred as “combine”. It mitigates the operation of various machines like cutting,threshing, feeding, isolating, cleaning, handling of grains as well as residue handling.

All these are quintessential owing to the fact that to set a combined perfectly, you need to identify which “machine” is not operating and which requires prior adjustment. Therefore, try to adjust one thing and that too at a time in order to ensure what worked and what didn’t.

The ultimate way to figure out this is to close down the entire setup. This will bring the machine in the field, covered with material as well as operating at the ground speed which you can easily detect.

Maintenance of Trouble spots

There are specific wear points on a combine which requires attention quite often which includes those parts that witness repeated friction, such as the roller chains on a corn head. If any chain that has loosened, extended, or become “messy,” it is quite likely that part will continue through harvest’s end lessens. Moreover, the failure of a chain-driven component can have adverse impacts anywhere on the machine which makes it a significant zone of concentration during a pre harvest combine inspection.

Make Harvesting Easier

This is all about the John Deere Combine Settings. If you follow this article from scratch, you will get to know every bit of it. The significance and the working process is provided in this informative blog.

You will get to know more about it on further updates. Apart from this, you can check the user manual for any instant help.