Rotary Combines

Ever since its invention and creation in 1834, the combine harvester has changed the face agriculture and how we manage the harvesting of crops. Of course those first combines were animal driven; using horses, mules, or ox teams. But even that rudimentary version of the combine was able to harvest over 50 acres of crops at speeds never seen before. The combine harvester has come a long way since then, and it has cemented itself as an indispensable tool on the farm. However, there have been advancements that have led to different mechanisms in the harvester. I speak, of course, of rotary combines for harvesting wheat, corn, soybean, etc. The rotary style machines have gained in popularity and are gaining in the market. But, in order to truly appreciate the rotary combine- you have to understand a bit more about where the combine has been, and what makes the rotary combine an entirely different beast.

The Beginnings of Combines

As you read before, the combine harvester was invented by Hiram Moore in 1834. It worked by using a cutting edge, known as a swathe, that was several meters long in order to cut down the crop harvests. Though they were initially driven by teams of work animals, the combine soon saw itself become powered by steam. Eventually, in 1911, the first self-propelled harvester was created. This was truly the beginnings of what would turn into the modern combine harvester.

The Basics of How a Rotor Combine Works

The modern combine harvester still employs the same basic task, but has been made to be faster and more efficient. They now operate with a series of removable heads or cutting drums, each designed for best performance on different kinds of crop. The standard header, or grain platform, uses a reciprocating knife cutter bar along with a revolving reel that feeds the crops into the auger after cutting. The process is largely the same for all of the different styles of heads, just performing slightly differently based on the crop.

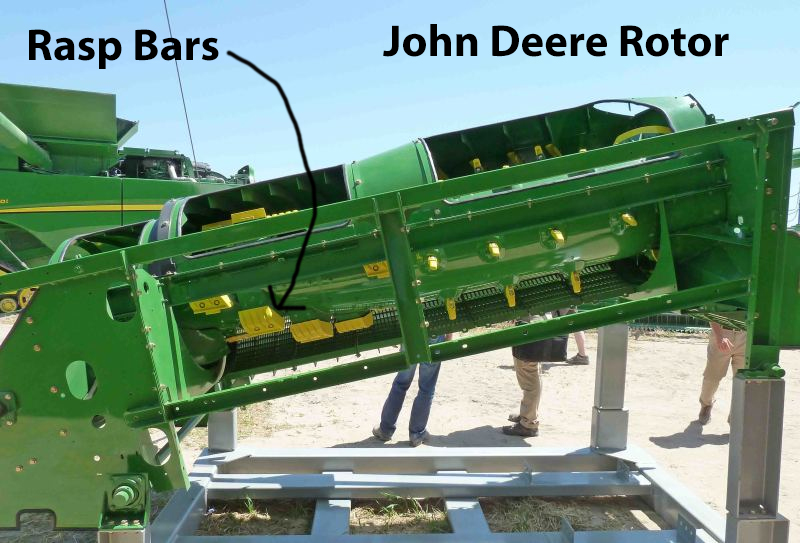

After the crops are fed into the auger, they are carried up into the feeder throat, or feeder house, by a chain and flight elevator. It is then fed into the thresher that uses a rotating threshing drum that has rasp bars attached. Beneath the combine drum containing the rasp bars are combine concaves. There is a gap between the rasp bars and concaves which separates the grain and the chaff from the straw. The concaves facilitate the threshing action against the rotor, rubbing the grain off the plant and allowing the grain to fall through the concave wires. The gap between the drum / rasp bars and the combine concaves can be adjusted depending on the crop harvested. The concaves for combines are a critical part of the threshing action and the concave settings are critical to retaining the grain harvested. Concaves are so important that many farmers buy aftermarket combine concaves for their combines to eliminate grain loss. It then passes everything through, where the grain and chaff will fall, while straw is carried away into straw walkers. The remaining grain is then separated out in the rotors.

The Rotary Combine Difference

In 1975, the first rotary combine was introduced. It used many of the same principles of the conventional combine harvester. However, it is in the grain separation that we see the difference in technique. Rather than feeding into the standard threshing drums with rasp bars, the rotary uses a helical rotating drum to perform the initial separation of the grain from the rest of the crop feed. A drastic departure from the rasp bar technique. Due to eliminating several parts from the process, we can get a smaller system with fewer moving parts. Also, the conventional system only gives one pass to allow grains to be separated. With the rotary drum, it gets rotated several times- giving the best chance at a greater yield.

The Benefits of Rotary Combines

The biggest benefit of rotary combines is its simplicity. Fewer moving parts means less to break down and maintain. Due to this, rotary combines have a greater capacity with a smaller footprint. If you tried to compare equal capacity between conventional and rotary combines- you would be looking at a conventional combine that is bigger than some houses. Also, the process in rotary combines is generally much gentler towards delicate crops like malt barley, peas, and lentils. Finally, with fewer components, the rotary combine tends to be much easier to clean as well.

The Problems of a Rotary Combine

The biggest drawback is that there is a learning curve to fine tuning a rotary combine. It will take time to find the right balance of power and positioning to get good results. This can lead to problems like over-pulverized straw. This is a common problem, but one that can be easily overcome with some time and adjustments. Rotor loss otherwise known as grain-loss is also a common problem with rotor combines, grain-loss is best described as grain that does not fall through the concaves and grates but rather gets passed onto the chaffer and goes out the back of the combine. This is a problem because that grain is lost rather than retained in the combine for sale. Aftermarket concaves stop rotor loss and make rotor combines much more efficient and profitable.

There are many debates online and around the table about what kind of combine is best. The most popular are John Deere combines and Case IH Combines. Every farmer has their preference, and they are happy to share it. However, in the end, you have to choose the combine harvester that is right for you. Just keep in mind that while conventional combines have history behind them, rotary combines offer some great advancements and an easier to maintain system. Do your research and choose which one is right for you.