If farmers stop the losses before, after, and during the harvesting operation, they stand to make a handsome profit. Case Concaves play an important role in this because they are the most important part of the harvester. Before we get to that, let us examine what the different stages are in a harvesting operation. Wastages occur at every stage and if we know them, we can prevent them.

Stages in Harvesting when Losses Occur

It is important to know which stages matter in the harvesting process to avoid wastage. In the case of the generic food supply chain, both upstream and downstream, the breakdown is like this:

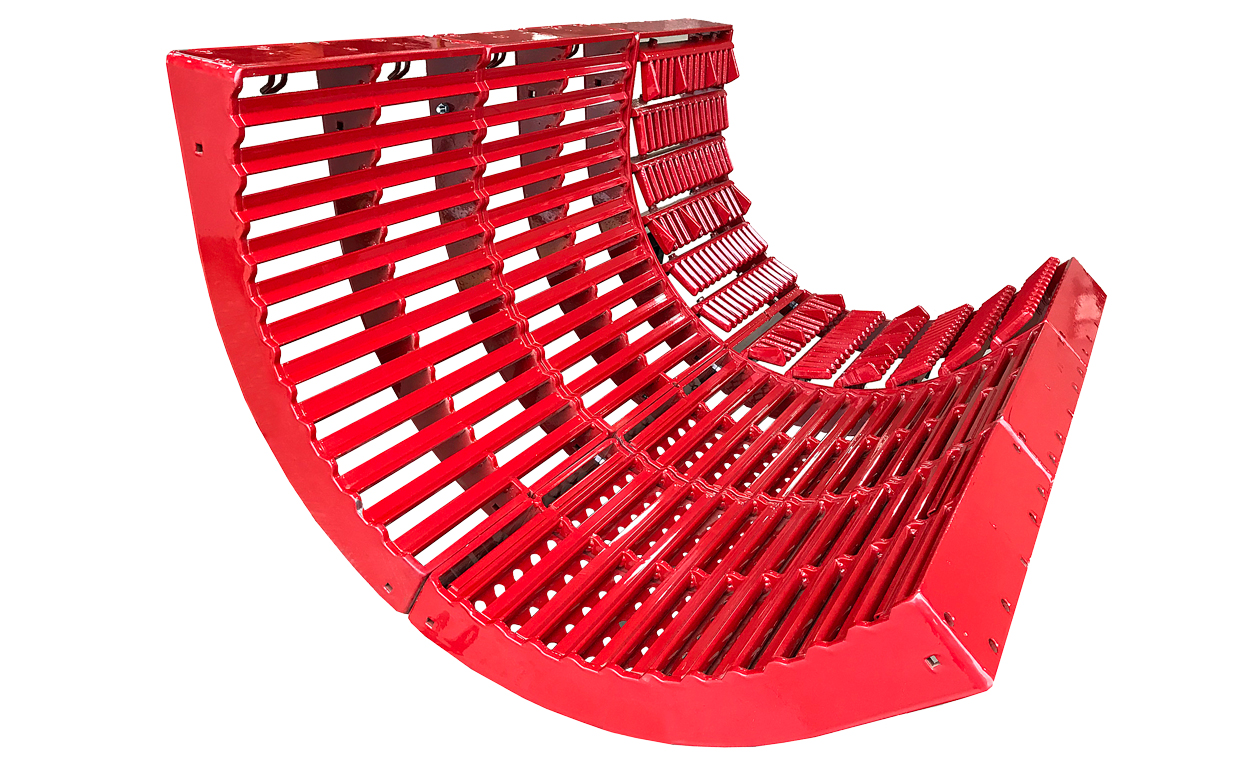

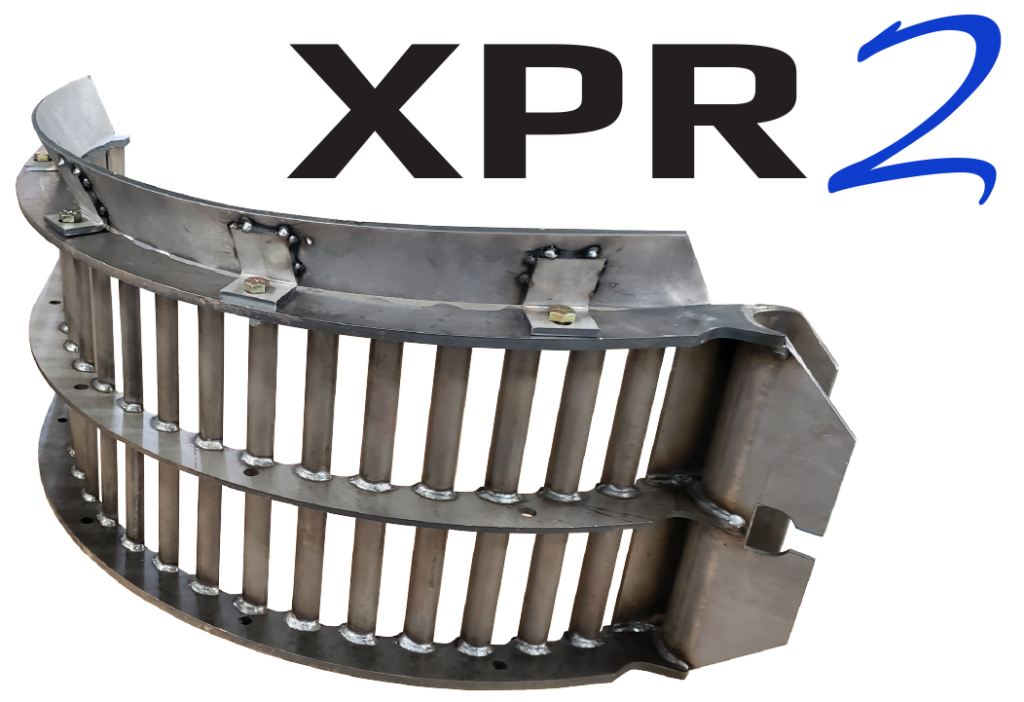

● Harvesting – Wastage takes many forms including edible crops left in the field and plowed into the soil. At times, the grain gets eaten by pests. You also have losses when you don’t choose the right time to harvest. And, there is wastage due to the damage to the grains during harvest. A large part of the damage and wastage is preventable if we use Case Concaves. These concaves stop rotor loss and give you 2-3 MPH more ground speed while harvesting.

● Threshing – Loss occurs due to poor threshing techniques.

● Drying and Transport – Here, the loss is due to spoiling and bruising. Lack of infrastructure is a contributing factor to this.

The Usefulness of Case Concaves

The use of Case Concaves benefits the farmer in many ways. These are:

- Use the same concave for all crops.

- Work with 30% more power.

- Avoid losses due to the rotor.

- Improve capacity by 70%.

- Increase harvest capacity with extended wear bars.

- Stop splits and fine cracks.

- Improved ground speeds.

- Perforated cover plates.

- Harvest up to 5000+ bushels in an hour.

- Superior threshing process.

Fine changes in the clearance help in the proper harvesting and threshing. When the clearance is too little, the grains get crushed. If they are too big, the grain remains in the pods and does not get threshed well.

Other Processes Involved in Harvesting

When one has a good knowledge of the stages, one is ready to deal with the losses. Here is another look at the loss-making stages in harvesting.

● Primary processing and packaging – These are process losses. Further, there is contamination in the process.

● Secondary processing and mixing – The same as before, the process losses occur along with contamination.

● Product evaluation – The choice of the wrong product or disregarding the right product will lead to wastage.

● Packaging – Inadequate packaging damages the grain. Losses occur due to spillage from sacks.

● Marketing – Damage occurring during transportation and spoilage. Losses happening due to poor storage and handling.

To make each stage of the harvesting process a profitable process, one has to keep an eye on a few things. One factor that makes the difference is choosing the proper octaves. So make your harvest pay you profits every time.

Advantage of Case Concaves

Now you know why Case Concaves are so popular with the farmers. They have in-built functionality that serves to help farmers make more profit. It makes sense to use these concaves when you are a newbie farmer with little experience because these concaves do your work for you.