If farmers stop the losses before, after, and during the harvesting operation, they stand to make a handsome profit. Case Concaves play an important role in this because they are the most important part of the harvester. Before we get to that, let us examine what the different stages are in a harvesting operation. Wastages […]

The John Deere Concaves and its New Model Systems

To get consistent grain quality, in a easy to operate and comfortable environment, farmers can now choose John Deere concaves for multiplying harvest output and save the most on time and fuel. The equipment helps in cleaning out the harvest with efficient threshing and separation process. It is simpler to manage the models that provide […]

Everything about Case Concaves and Their Settings

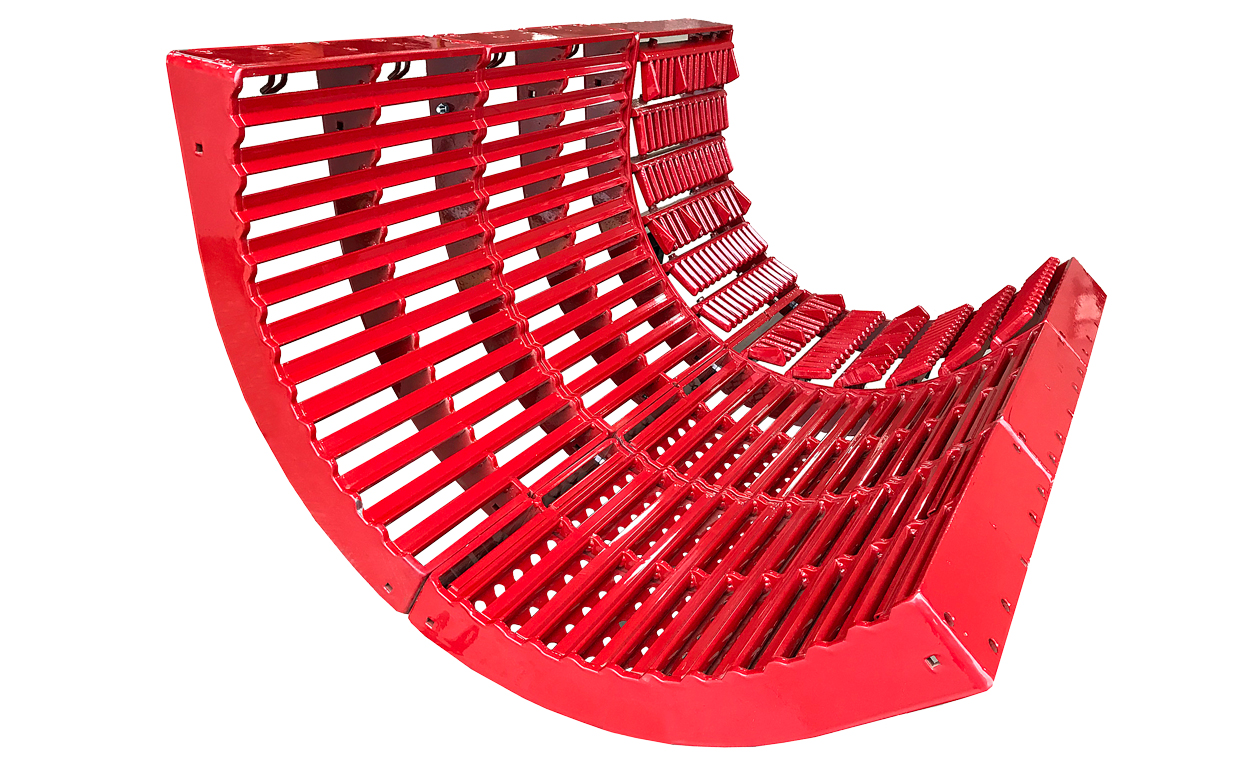

A combine concave plays an important role in the quality of the harvested crop, both in threshing and separating. The threshing involved freeing the seeds from its plants and separation process moves away these seeds. In case concaves, the friction with rotating cylinder and incoming crops causes the threshing procedure in a much improved manner. […]

Combine Concaves

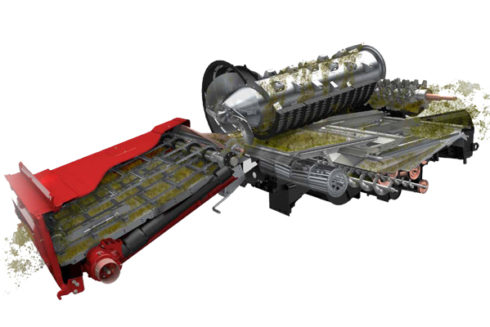

Combine Concaves Purpose

Whether your harvest is a John Deere or a Case IH combine, your concave plays a vital role in the quality of your harvested crop. The combine concave performs two important functions- threshing and separating. The threshing process frees the seeds from the plants. Then the separation process moves the seeds away from the chaff.

How Combine Concaves Work

In concaves for combines, friction among the rotating cylinder, the incoming crop, and the concave results in the threshing process. The clearance between the cylinder and the concave is adjustable. Once the crop enters the clearance, it gets squashed by the cylinder against the concave and smaller parts start to sift through the openings. As a result, the grain is separated from the plants.

The clearance distance, the bar and wire patterns of the concave, the speed of the rotor, and the crop types determine how clean the samples turn out in the grain tank. It takes a bit of experience to understand how all these factors influence the process.

Setting Concaves For Harvest

Striking a balance between the cylinder rotating speed and the concave clearance is like walking a tightrope. The purpose of the clearance between the cylinder and the concave is to regulate the material flow. If there is too much space, then the grains will not separate. If it is too tight, then it results in damaged product. It is a good idea to consult the combine operation manual. Start with the recommended clearance settings. Then adjust according to the field conditions.

Concaves come with different types of bars and wires. The straight bars of the concave run parallel and the curved wires are perpendicular to the rotating axis.Narrow-wired concaves are great for small grains like wheat and barley. The narrow spacings between the wires allow the small seeds to sift through. The bars are square-edged. Wide-wired ones are for crops like corn or beans. The design is similar to the narrow-wired ones. But there is more spacing between the wires to accommodate larger grains.

Round bar concaves are great for high-volume situations. They have round bars but no wires. Some advocate for helical round bars, but the diagonal pattern makes it harder for unthreshed grain to escape. So it is a great option where you need to ensure cleaner grain. You can also install it in the front concave position to help improve the yield of the other designs.

Besides the concave clearance and design patterns, you can use cover plates to improve the threshing process. The plates are used to strategically cover up certain parts of the installed concaves to let the material stay longer between the threshing cylinder and the concave.

Why Aftermarket Combine Concaves?

Understanding the available options will help you get the best performance from your combine. Stock round bar concaves perform well for picking corn in ideal conditions, however they fall short in higher-moisture or high bushel harvesting. Small wire concaves do well in small grains but there you are still having to change out concaves. In addition, all stock concaves lack the capacity needed to get the amount of threshed grain out without overloading the separation section.

Estes combine concaves thresh all crops, so one set of concaves and no more backbreaking work changing them out. Also, they are engineered with superior technology to thresh better, clean better and to get what you harvest. No more volunteer crop or dockage. Take back your bushels and reach out to us for more information below.