Combine concave has been a crucial component in shaping modern agriculture. The introduction of this device meant that farmers no longer needed to work as hard, which fruitful resulted into an increase on their productivity by over 85%. Combine harvesters revolutionized modern agriculture because they allowed farmers to do more with less manpower.

In the 19th century, over 85% of Americans were employed on farms but that number dropped dramatically after machinery like combines came into existence during World War I era (1914-18). These agricultural innovations made it possible for one worker or even just two assistants per machine can perform tasks which previously required multiple people working together at once such as beating stalks into straws before winnowing them by wind alone

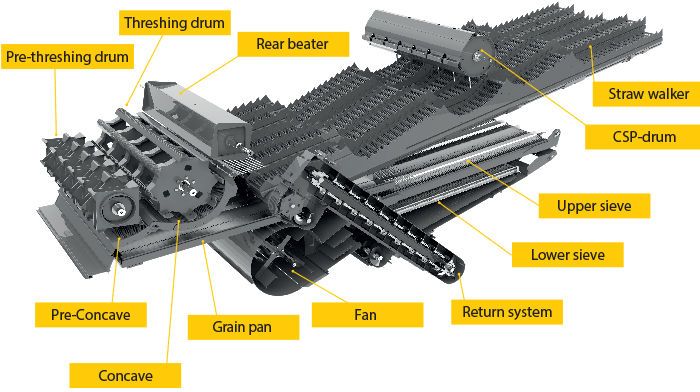

The concave of a combine harvester play vital role in harvesting. It helps to separate the Chaff (palea and Glumes) from the Kernel (grain). The Kernel falls through the concave and into the hopper while the light Chaff material gets blown out through the chaffer or straw walkers.

The concave is a spinning cylinder with sharp, serrated edges. It has a series of circular openings that are sized according to the type of crop it is used for. The shape and size of the openings allow only the largest kernels of grain to fall through while deflecting lighter materials like chaff and straw.

Concaves can be made from various materials such as stainless steel or plastic. It is important to keep them clean and in good condition so that they can effectively separate grain from chaff without becoming clogged or damaged by stray stones or other foreign objects in the field.

Concave maintenance should be an integral part of any combine harvester maintenance plan. Apart from keeping the concave clean and free of debris, it should also be checked and adjusted periodically to ensure that the openings are still the correct size for your particular crop.

Concave technology has advanced considerably over the years, with newer models equipped with sensors and technology that can automatically adjust settings based on field conditions and crop type. But regardless of how sophisticated a concave might be, its basic function remains the same: separating grain from chaff in order to increase harvest efficiency and improve yield.

Overall, the concave is an essential component of any combine harvester that helps to maximize productivity by ensuring efficient separation of grain from lighter materials like straw and chaff. Whether you’re a farmer or just enjoy watching combines at work, taking a closer look at this important piece of equipment is sure to be an enlightening experience!

Guide to Choose Best Combine Concave Manufacturers

To help you find the best combine concave manufacturers and suppliers, here are some tips on what to look for when choosing a supplier.

1. Start by considering the materials used in manufacturing the concave and other components of your harvester. Look for suppliers that use high-quality, durable materials that will stand up to regular wear and tear without losing their effectiveness or breaking down over time.

2. Next, consider how long the manufacturer has been in business and whether they have experience working with different types of agricultural machinery and crops. An established company is more likely to deliver quality products that meet your specific needs, regardless of whether you’re harvesting grains, fruits, or other types of crops.

3. Finally, take a look at the manufacturer’s customer service and support. A good concave supplier should be able to guide you through choosing the right models for your harvester, as well as provide advice on how to maintain and troubleshoot any issues that may arise over time.

If you’re looking for a reliable and high-quality concave supplier for your combine harvester, start by doing some research online to learn more about the top manufacturers in your area. With their quality materials, experience, and customer support, you can feel confident that your harvest will run smoothly every time.